A large amount of construction waste generated during the urbanization construction process, including construction waste, waste concrete, prefabricated panels, mortar, asphalt blocks, etc. These construction wastes not only pollute the environment, but also occupy large land area. Hence, recycling them not only protects the ecological environment, but also creates considerable economic benefits. Camelway provides special mobile processing solutions for the comprehensive recycling the construction waste. In addition, its production capacity is up to 300 tons per hour.

Process

1. Screen out the muck, non-metal materials.

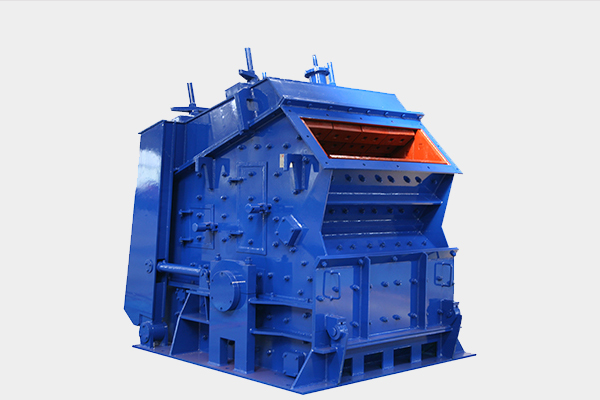

2. Remove the dust.

3. Primary crushing, secondary crushing and particle shaping.

4. The screening system grades the final material.

5. The conveyor system delivers qualified materials to different yards.