Camelway Stationary Central Mix Concrete Batching Plant has been designed for producing high-quality concrete. It has the advantages of large output, high efficiency, high stability and high specification, which adopts reliable and flexible components, making it easy to maintain and own a low failure rate. It is widely used in various projects such as roads and bridges, ports, tunnels, dams and buildings.

Camelway Machinery offers various stationary concrete batching plants with capacity of 50 to 540 m³/h. Concrete Plants with skip hoists makes it possible to produce high-quality ready-mixed concrete in smaller footprint; Concrete Plants with insulation or refrigeration systems makes it possible to produce concrete in cold or hot areas; Concrete Plants equipped with vertical shaft planetary mixer or enhanced twin-shaft mixers can be used in producing high-grade concrete production above C50.

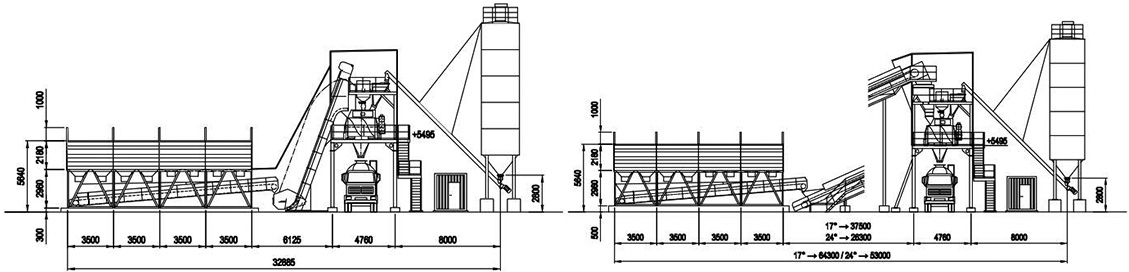

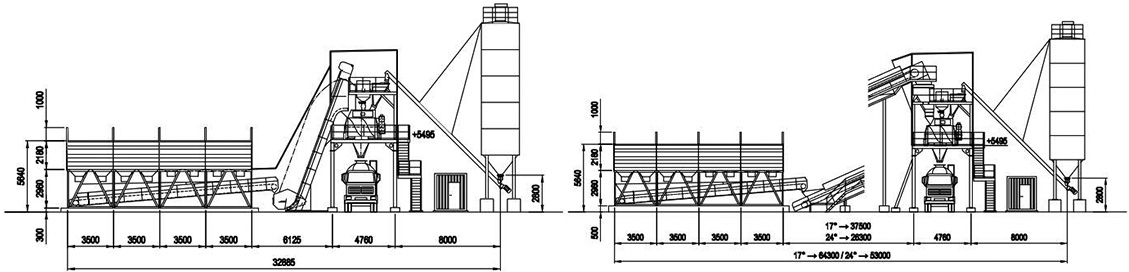

2 Types of Stationary Batching Plant Layout

FAQ

1. Stationary Concrete Batching Plant Price?

The price of the stationary concrete plant is affected by multiple factors, such as raw material cost, logistics transportation cost, labor cost, ect. In addition, the configuration of the concrete plant is tailored to the customer's own demands. Due to different configuration, which means that the price is changed, so we are unable to provide online quotes. We will send you the configuration plan and quotation after you send us your requirements.

2. Do you provide wearing parts?

The wearing parts of the concrete plant include mixing blades, lining boards, transportation belts, sealing strips, dust filter elements, etc. When you purchase our concrete plant, we will offer you some wearing parts for the occasional need. In the future, our after-sales manager will provide corresponding wearing parts according to the maintenance situation.

3. Is it used to produce wet concrete?

Yes. Stationary Concrete Batching Plant is Central Mix Plant that mix all materials including cement, aggregate, ad-mixture and water together in a central mixer. While for dry concrete applications, you may need a dry concrete batching plant which does not equip with central mixer.

4. Is it suitable for producing roller compacted concrete?

Sure. Stationary Concrete Batching Plant suitable for almost all kinds of concrete include Rcc and other low slump concrete. For RCC, the stationary concrete batching plant has the advantage of higher precisions on the dosages while the continuous mixing plant has the advantages of higher outputs.

Notes:

1. The capacity of the concrete plant is theoretical productivity, and the actual capacity may be lower than the theoretical value.

2. The floor space refers to the footprint of the main body of the concrete batching plant. It does not contain the floor space of the aggregate yard, living area, laboratory and other functional areas. The concrete plant of the same type may adopt different structural forms according to the needs of users. The footprint and standard footprint are different.

3. Discharging height is the receiving height of the standard concrete mixer truck which be adjusted according to the actual need.