Popular: Batching Plant Price

Established in 1983, Henan Camelway Machinery Manufacture Co., Ltd. is mainly engaged in R&D and manufacturing of high-tech equipment, such as construction equipment and crushing equipment, as well as providing technical solutions and supporting products.

![]() Your personal information will be kept confidential

Your personal information will be kept confidential

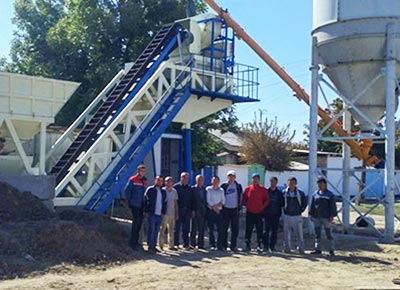

Camelway Machinery provides a wide range of Concrete Batching Plants along with all components including mixers, batchers, cement silos, etc, which are widely used for the projects such as buildings, bridges, roads, airport, etc.

Camelway is committed to providing customers with competitive concrete production and gravel-aggregate production solutions. Camelway solutions are recognized by global clients because of quality service and premium products. The customer case can provide a reference for your project, please feel free to contact us for more project details.

Model:HZS50 Region:Nigeria

Model:HZS75 Region:Philippines

Model:YHZS60 Region:South Africa

Model:HZS90 Region:Indonesia

Camelway Machinery provides a wide range of Concrete Batching Plants along with all components including mixers, batchers, cement silos, etc, which are widely used for the projects such as buildings, bridges, roads, airport, etc.

Camelway group is always ready to help you, no matter what kind of technical consultation, program design, equipment installation, operation training or after-sales service. There are experienced technical engineers, installation engineers, sale managers in our professional team, what we do is not only helping you to achieve your recent business goal, but also providing reasonable advice to keep you competitive in your market.

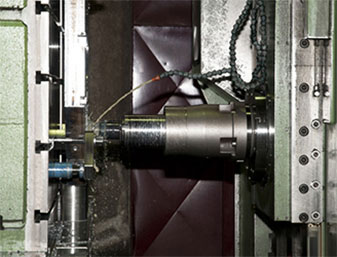

We have more than 160 highly sophisticated technicians, more than 200 advanced casting production equipment.All products have passed ISO9001 international quality certification system and successfully serve customers in many countries and regions all over the world.

We have more than 160 highly sophisticated technicians, more than 200 advanced casting production equipment

With excellent product quality and after-sales service, Camelway's products and services quickly cover more than 100 countries and regions around the world. We look forward to working with you in your next project.