The batching methods in concrete manufacturing processes

The batching methods in concrete manufacturing processes

In high quality concrete producing processes, choosing an appropriate batching method plays an essential role. There are two common methods to be selected: volume batching and weigh batching.

Generally speaking, volume batching is not a preferred way the concrete producer may choose for proportioning the raw materials including Portland cement, aggregates and some admixtures, because there is some difficulty in measuring granular materials by volume. And for the measurement of moist sand in a loose condition will be weighing much less than the dry compacted sand at the condition of same volume. Therefore, the effect of bulking should be considered for moist fine aggregates. To sum up, volume batching method is just suitable for unimportant concrete or for any small jobs.

camelway concrete batching plant supplier

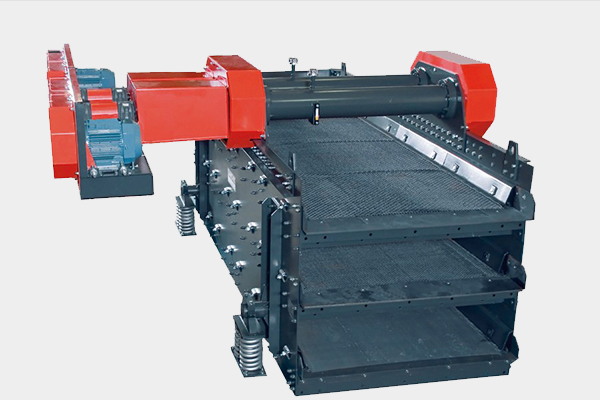

Compared with volume batching method, weigh batching is a better way for most types of concrete production. It is more precise method of materials measurement with the features of high accuracy, flexibility and simplicity. The large concrete batching plants are often equipped with automatic weighing systems while on large work sites, the weigh bucket type of weighing equipment will be adopted.

Based on the mix ratio the weight of materials required for preparing specimens of each mix were found and the materials were mixed with sufficient quantity of water and the concrete was prepared.