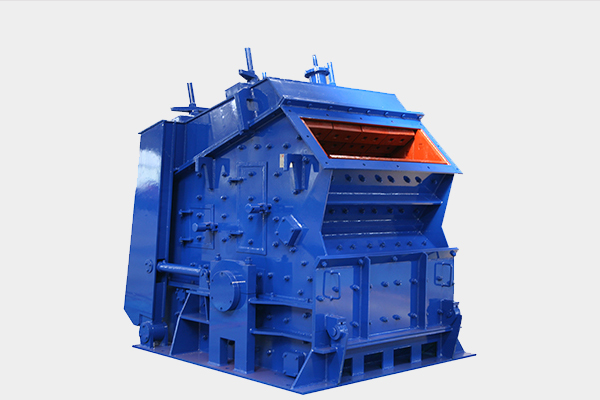

Impact Crusher

Impact Crusher

Impact Crushers(Impactors) comprise a lined chamber within which revolves a rotor on a horizontal axis. The rotor is fitted either with swing hammers located by pins or blow-bars of alloy steel located by mechanical or hydraulic clamps. The hammers or blow bars impart impact to the rock resulting in comminution that is energy efficient and a typically cubical product shape. Impact with the rotor, the chamber liners (breaker plates) and interparticulate collision all contribute to comminution. Reduction ratios of 20:1 are achievable in a single stage and even 40:1 for double rotor impactors. The impactor thus offers several potential advantages of high reduction ratio, low capital and operating cost, ease of installation and low head room requirement and good product shape. Product size can be varied within limits by changing rotor speed and the clearances between rotor and liners.

The major limitation to the application of impactots is abrasive wear. Abrasive wear necessitates the costly replacement of hammers or blow-bars but, more importantly, results in loss of operating time, and low availability. Therefore, impactors tend to be restricted to crushing of non-abrasive rocks e.g. non-siliceous limestones and dolomites and to nonaggregate minerals e.g. coal, gypsum, salt. It has been stated that impactors are not suitable for rocks containing more than 5% free silica. Swing-hammer type impactors are generally applied to the production of the finer sizes of aggregate but impact becomes ineffective at a particle size less than about 3 mm.

Impact Crusher features

The recent developments have mainly concerned the fixed blow-bar type which is now available as a primary crusher that can reduce very large lumps by a combination of impact and 'nibbling' actions. The use of a few large blow-bars forged from special alloys in place of many hammers and the design of the crushing chamber to permit very rapid access for maintenance, e.g. hydraulically actuated mechanisms for opening the casing and clamping wearing items, has overcome to some extent the principal disadvantage of impactors. They are now applied to the crushing of mineral ores, slags and siliceous limestones. Abrasive gritstones, quartzites and even basalt may also be crushed at the final stage by impactors when the value of the cubical shape produced justifies the cost, e.g. surface chippings for roads or decoration.

In most cases the impactor operates in open circuit with no control upon product size other than clearances between rotor and liners, speed of rotation and feed rate. Caged hammer mills are available which include a discharge grating but the problems of wear and blockage can be severe and their use is usually restricted to soft minerals such as clays, coal, etc.