Mobile Concrete Batching Plant For Sale Malaysia

The mobile concrete batching plant was developed on the basis of the fixed concrete batching plant. ,He concentrated the material weighing, conveying, mixing, unloading and automatic control systems of the concrete batching plant on the semi-trailer unit. On the premise of meeting the output and quality of the concrete batching plant, it has the characteristics of flexible movement, rapid disassembly, small footprint, simple storage management, high degree of automatic speaking, and close access to the construction site.,Suitable for various road, bridge, airport and other field projects,The new mobile batching plant is based on the structure of the traditional mobile batching plant, improves the internal configuration and performance. Is the increase in output,With the continuous development of society and economy, the environmental protection requirements of concrete enterprises in various places are constantly increasing. Improved various requirements for environmental protection configuration, This article will introduce the characteristics of the new mobile concrete mixing plant and its environmentally friendly configuration.

Mobile Concrete Batching Plant Features

The new mobile concrete batching plant adopts a box-type fully enclosed structure design. According to each box structure, it is divided into three main parts: the main body, the batching station, the external box and the upper box. The operation process, operation mode, and maintenance of the mobile batching plant are consistent with the fixed concrete batching plant, The new mobile concrete batching plant has the following characteristics: flexible and convenient. This equipment integrates a variety of operations such as material storage, metering, conveying, mixing, and lifting.

Mobile Concrete Batching Plant Structure And Process

The mobile concrete batching plant is composed of a mixing system, a gravel weighing system, a cement weighing system, a water and liquid admixture weighing system, a gas system, a mobile system, an electronic control system, and a control room assembly.

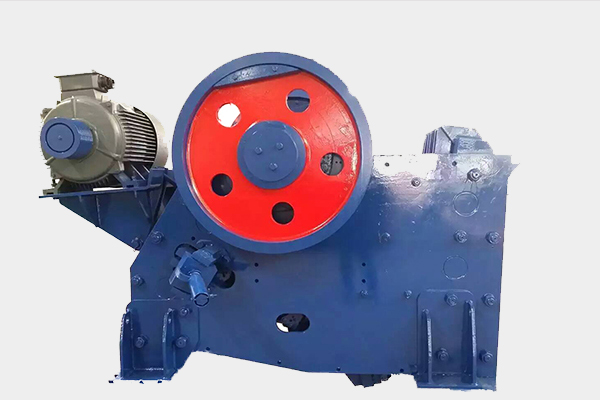

Mixing system

The mixing system is composed of a concrete mixer, a cover, a funnel, a host chassis, and legs.

(1) concrete mxier

The concrete mxier is composed of a mixing driving device, a mixing device, a mixing tank, a discharging mechanism, a gear cover and the like.

(a) Stirring drive device

The stirring driving device is a pair of meshed open gears driven by two motors, which respectively drive the two open gears on the stirring shaft to drive the two stirring shafts to rotate at the same speed in the opposite direction.

(B) Stirring device

The stirring device is composed of left and right stirring shafts, stirring arms, stirring blades and shaft end seals.

(c) Unloading system

The air cylinder drives the crank to drive the discharge door installed at the bottom of the mixing tank, so that the discharge door can be rotated. The discharge door is sealed by adjusting the position of the sealing strip between the discharge door and the mixing tank. A stroke switch is installed on each side of the crank of the discharge door, which is used to transmit the opening and closing signal of the discharge door.

(2) Host chassis

The chassis is welded by grooved steel, the upper plane is connected to the mixing host, the lower plane is connected to the legs and the funnel, the end is connected to the bracket, and the two sides are connected to the platform.

(3) Outriggers

The legs are under the mainframe chassis, and together with the brackets, the mainframe chassis is raised.

Gravel weighing system

The gravel weighing system is composed of a gravel storage hopper, a gravel weighing belt scale, a sensor assembly, a support frame, and a gravel conveyor inclined conveyor.

Cement silo weighing system

The cement bin weighing system consists of a cement bin, a screw conveyor, a cement weighing hopper, and a sensor assembly.

1) Screw conveyor

The screw conveyor includes a motor, a reducer, an input tube, an input screw, an intermediate support, an output screw, a rear support, etc.

2) Cement weighing

Cement weighing hopper is suspended from the bracket by the cement sensor assembly. Weighing hopper has a butterfly valve at the bottom,The butterfly valve is driven by the cylinder to open and close. When transporting and not in use for a long time, The cement weighing hopper is suspended from the bracket by three booms, De-stress the sensor.

Mobile batching plant for sale Malaysia

Because Malaysia has a large territory, Concrete is easy to segregate during transportation of concrete,So the mobile concrete batching plant is very suitable for a vast country like Malaysia.

camelway specializes in producing mobile concrete batching plant equipment, our company can provide customers with mobile concrete batching plant price, mobile concrete batching plant product information, mobile concrete batching plant installation instructions, etc. Various solutions, we are mobile concrete Manufacturer of batching plant, you can contact us to get what you want.